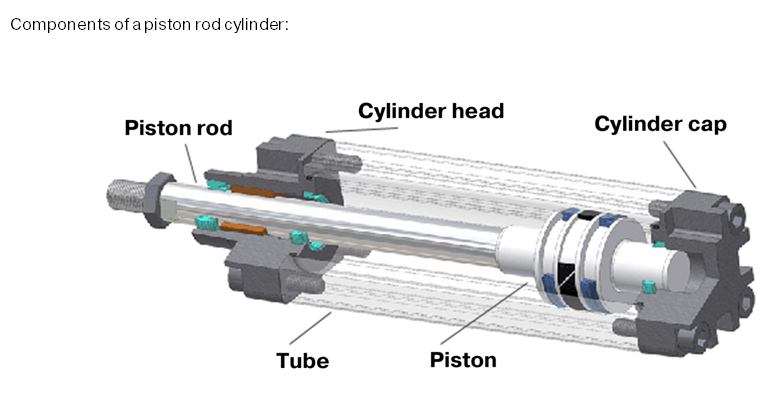

Amasilinda womoya (enziwe ngeshubhu yesilinda somoya, i-piston rod, i-cylinder cap), ebizwa nangokuthi amasilinda omoya, ama-pneumatic actuators, noma ama-pneumatic drives, angamadivayisi alula uma kuqhathaniswa asebenzisa amandla omoya ocindezelwe futhi awenze ukunyakaza okulandelanayo.Ukunakekelwa okungasindi nokuncane, amasilinda womoya ngokuvamile asebenza ngesivinini esiphansi namandla amancane kunozakwabo we-hydraulic noma kagesi, kodwa ayinketho ehlanzekile nengabizi kakhulu yokunyakaza okuthembekile komugqa ezindaweni eziningi zezimboni.Umklamo ovame kakhulu uqukethe isilinda noma ishubhu elivalwe emikhawulweni yomibili, elinekepisi ekugcineni nekhanda ngakolunye uhlangothi.I-cylinder iqukethe i-piston, ehlanganiswe nenduku.Induku ingena iphinde iphume kwelinye icala leshubhu, iqhutshwa umoya ocindezelwe.Izitayela ezimbili eziyinhloko zikhona: ukwenza okukodwa kanye nokwenza kabili.

Idizayini yesilinda somoya:

Kumasilinda womoya asebenza kanye, umoya unikezwa ngembobo eyodwa uye ohlangothini olulodwa lwepiston, okubangela ukuthi induku yepiston inwebe ibheke endaweni eyodwa ngomsebenzi ofana nokuphakamisa into.Olunye uhlangothi lukhiphela umoya endaweni ezungezile.Ukunyakaza okubheke kolunye uhlangothi kwenzeka kaningi kusetshenziswa isiphethu esisebenza ngomshini, esibuyisela induku yepiston endaweni yayo yasekuqaleni noma eyisisekelo.Amanye amasilinda asebenza kanye asebenzisa amandla adonsela phansi, isisindo, ukunyakaza komshini, noma isiphethu esifakwe ngaphandle ukuze sinikeze amandla i-stroke ebuyayo, nakuba le miklamo ingavamile kakhulu.Ngokuphambene, amasilinda womoya asebenza kabili afaka izimbobo ezimbili ezinikeza umoya ocindezelwe womabili anwebe futhi ahoxise i-piston rod.Imiklamo esebenza kabili ijwayeleke kakhulu kuyo yonke imboni, ngokulinganiselwa ku-95% wezinhlelo zokusebenza ezisebenzisa lesi sitayela samasilinda.Kodwa-ke, kwezinye izinhlelo zokusebenza, isilinda esibambayo esisodwa siyisixazululo esingabizi kakhulu nesifanele.

Kusilinda esibambayo esisodwa, idizayini ingaba "indawo ephansi yokususa" ngokubuya kwentwasahlobo, noma "indawo eyisisekelo ukuhlanganisa" nokunwetshwa kwentwasahlobo.Lokhu kuncike ekutheni umoya ocindezelweyo usetshenziselwa ukunika amandla i-out-stroke noma i-in-stroke.Enye indlela yokucabanga ngalezi zinketho ezimbili ukusunduza nokudonsa.Emklamweni wokusunduza, umfutho womoya udala i-thrust, ephusha ipiston.Ngomklamo wokudonsa, umfutho womoya ukhiqiza i-thrust edonsa ipiston.Uhlobo olucaciswe kabanzi kakhulu ingcindezi enwetshiwe, esebenzisa isiphethu sangaphakathi ukubuyisela ipiston endaweni yayo eyisisekelo lapho umoya uphela.Enye inzuzo yedizayini ebambe iqhaza elilodwa ukuthi uma kwenzeka ilahleka amandla noma ingcindezi, i-piston ibuyela ngokuzenzakalelayo endaweni yayo eyisisekelo.Okubi kwalesi sitayela amandla okukhiphayo athi angashintshi ngesikhathi sokushaya okugcwele ngenxa yamandla entwasahlobo aphikisayo.Ubude be-stroke bubuye bukhawulwe yisikhala esidingwa intwasahlobo ecindezelweyo, kanye nobude bentwasahlobo obutholakalayo.

Futhi khumbula ukuthi ngamasilinda abamba eyodwa, omunye umsebenzi uyalahleka ngenxa yamandla entwasahlobo aphikisayo.Lokhu kuncishiswa kwamandla kumele kucatshangelwe uma kufakwa usayizi walolu hlobo lwesilinda.Ububanzi kanye ne-stroke yizinto ezibaluleke kakhulu okufanele zicatshangelwe phakathi nezibalo zokulinganisa.Ububanzi bubhekisela kububanzi bepiston, obuchaza amandla ayo ngokuhlobene nomfutho womoya.Ama-cylinder diameters atholakalayo achazwa uhlobo lwesilinda kanye ne-ISO noma amanye amazinga.I-Stroke ichaza ukuthi i-piston ne-piston rod ingahamba amamilimitha amangaki.Umthetho ojwayelekile ukuthi uma ibhore yesilinda inkulu, amandla amakhulu aphumayo.Ubukhulu obujwayelekile bobhore besilinda busukela ku-8 kuye ku-320 mm.

Ukucatshangelwa kokugcina isitayela sokukhuphuka.Kuye ngomkhiqizi, ukucupha okuningi kuyatholakala.Ezinye ezivame kakhulu zihlanganisa ukukhweza kwezinyawo, ukukhweza komsila, ukukhweza kwe-pivot engemuva, ne-trunnion mount.Inketho engcono kakhulu izonqunywa uhlelo lokusebenza oluthile nezinye izingxenye zesistimu.

Isikhathi sokuthumela: Aug-19-2022