I-HLQ/STM SLIDE TABLE AIR CYLINDER ALUMINIUM TUBING

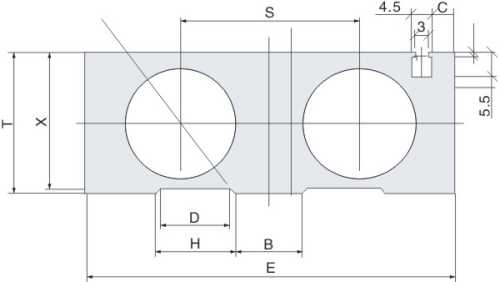

Uchungechunge lwe-STM

| NO | d | E | X | T | D | H | B | C | S |

| 1 | Φ10 | 44 | 16 | 17 | 8 | 10 | 8 | 1.5 | 18 |

| 2 | Φ16 | 59 | 22 | 23 | 11 | 13 | 14 | 1.5 | 30 |

| 3 | Φ20 | 68 | 25 | 26 | 13 | 16 | 17 | 1.5 | 35 |

| 4 | Φ25 | 82 | 31 | 32 | 16 | 18 | 15 | 5 | 40 |

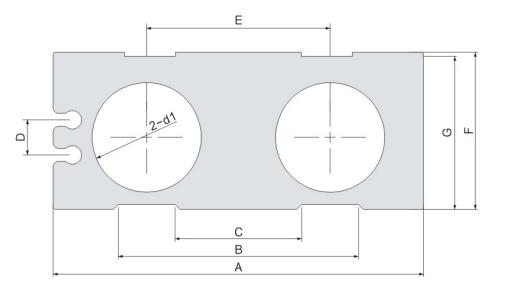

I-HLQ (φ6-25) Uchungechunge Lwethubhu Yethebula Leslayidi Leslayidi

| NO | 2-d1 | A | B | C | D | E | F | G |

| 1 | φ6 | 30.6 | 17.4 | - | 5.2 | 12 | 11.5 | 10.9 |

| 2 | φ8 | 40.6 | 24 | - | 5.4 | 17 | 14.1 | 13.5 |

| 3 | φ12 | 50.8 | 28 | 12 | 6 | 20 | 19.4 | 18.5 |

| 4 | φ16 | 60.8 | 38.6 | 15.4 | 6 | 24 | 24.3 | 23.3 |

| 5 | φ20 | 70.8 | 44 | 20 | 6 | 32 | 29.6 | 28.8 |

| 6 | φ25 | 84.8 | 55 | 29 | 8 | 42 | 35.8 | 34.9 |

I-Material ye-Aluminium Alloy Profile I-Aluminium pneumatic cylinder tube: i-aluminium alloy 6063 T5

Ubude bethu obujwayelekile bungu-2000mm, uma udinga obunye ubude, sicela usazise ngokukhululekile.

Indawo ene-anodized: Ishubhu yangaphakathi-15±5μm Ishubhu yangaphandle-10±5μm

Izivumelwano zokuklama i-FESTO, i-SMC, i-Airtac, i-Chelic njll.

Ivumelana nezinga le-ISO 6430 ISO6431 VDMA 24562 ISO15552 njll.

Isetshenziselwa isilinda esijwayelekile, isilinda esicwebezelayo, isilinda esincane, isilinda se-Dual Rod, isilinda sama-Slide, isilinda seThebula lama-Slide, i-Gripper njll. Futhi kwamanye amasilinda akhethekile.

Ukwakhiwa Kwekhemikhali:

| Ukwakheka Kwamakhemikhali | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Ukucaciswa:

| Ukuqina Kwengcindezi (N/mm2) | Amandla Esivuno (N/mm2) | I-Ductility (%) | Ukuqina Kobuso | Ukunemba Kobubanzi Bangaphakathi | Ubulukhuni bangaphakathi | Ukuqondile | Iphutha lokuqina |

| Sb 157 | S 0.2 108 | S8 | I-HV 300 | I-H9-H11 | <0.6 | 1/1000 | ± 1% |

I-Tolerance Of Aluminium Alloy Tube:

| UKUBEKEZANA KWETHUBU LE-ALUMINIUM | ||||||

| Bore Size | UKUBEKEZANA | |||||

| mm | I-H9(mm) | I-H10(mm) | I-H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

I-FAQ:

Q1: Yiziphi izinhlobo zetafula elishelelayo Amasilinda e-pneumatic akhona?

A: Imodeli ine-MXS ne-STM yesilinda somoya

Q2: Liyini ithebula lesilayidi isilinda somoya?

A: Ithebula elishelelayo I-Pneumatic Cylinder: Ithebula le-Pneumatic sliding liyindlela yokushayela esetshenziswa kabanzi embonini ye-automation.Isetshenziswa kabanzi emkhakheni wamathuluzi omshini, imishini ye-automation kanye namarobhothi.Ngokuvamile ishayelwa umoya ocindezelwe, futhi ukunyakaza okuqondile kwesilayidi kubonakala ngokudluliswa okuhlanganisiwe kwamabhola anembayo nama-rails ama-slide alayini.

Q3: Ingabe zikhona izinzuzo?

A:

1 Ukuhlanganiswa okuhlangene kwetafula elishelelayo Ithebula lomsebenzi we-Pneumatic Cylinder kanye ne-Pneumatic Cylinder;

2. I-Pneumatic Cylinder enembayo ifanele amatafula okushelela womoya ukuze ahlanganiswe ngokunemba;

3. Ukuqina okuphezulu / ukunemba okuphezulu, idivayisi yokuzikhethela eshintshwayo (0-5mm);

4. Ithebula elishelelayo I-Pneumatic Cylinder isebenzisa umhlahlandlela webhola eliphambene, elinokungqubuzana okuphansi futhi elikwazi ukubona ukunyakaza okushelelayo ngaphandle kokuxega;

5. Inhlanganisela ye-Pneumatic Cylinder kanye ne-worktable kunciphisa usayizi jikelele;

6. Isakhiwo se-Double-Pneumatic Cylinder samukelwa ukuze sithole amandla aphumayo aphindwe kabili;

7. Uhlobo lwendandatho eyakhelwe ngaphakathi kazibuthe, inkinobho kazibuthe ingafakwa.

8. Ithebula le-pneumatic sliding table ye-pneumatic Pneumatic Cylinder ngokuvamile lisetshenziswa njengokuthuthwa nokuthutha amathuluzi anembayo, futhi ukunemba kuphakeme uma kuqhathaniswa.

Q4: Uyini usayizi wokubhoboza we-MXS?

A: Usayizi we-bore une-Dia 6mm, i-Dia 8mm, i-Dia12mm, i-Dia16mm, i-Dia20mm