I-DFM Series Guide Rod Aluminium Air Cylinder Tubes

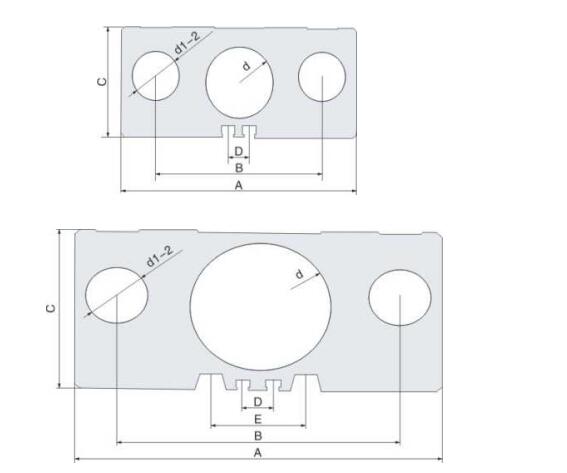

DFM Series Umdwebo

| NO | d | d1-2 | A | B | C | D | E |

| 1 | φ12 | φ11.5 | 60 | 41 | 28 | 10 | - |

| 2 | φ16 | φ13 | 67 | 46 | 32 | 8.1 | - |

| 3 | φ20 | φ15.5 | 83 | 58 | 36 | 10 | - |

| 4 | φ25 | φ17.5 | 95 | 68 | 44 | 10 | - |

| 5 | φ32 | φ20 | 110 | 78 | 49 | 10 | - |

| 6 | φ40 | φ22.5 | 120 | 88 | 54 | 13.5 | - |

| 7 | φ50 | φ27.5 | 148 | 110 | 64 | 16 | 40.5 |

| 8 | φ63 | φ27.5 | 162 | 125 | 78 | 13.5 | 42 |

I-Material ye-Aluminium Alloy Profile I-Aluminium pneumatic cylinder tube: i-aluminium alloy 6063 T5

Ubude bethu obujwayelekile bungu-2000mm, uma udinga obunye ubude, sicela usazise ngokukhululekile.

Indawo ene-anodized: Ishubhu yangaphakathi-15±5μm Ishubhu yangaphandle-10±5μm

Izivumelwano zokuklama i-FESTO, i-SMC, i-Airtac, i-Chelic njll.

Ivumelana nezinga le-ISO 6430 ISO6431 VDMA 24562 ISO15552 njll.

Isetshenziselwa isilinda esijwayelekile, isilinda esicwebezelayo, isilinda esincane, isilinda se-Dual Rod, isilinda sama-Slide, isilinda seThebula lama-Slide, i-Gripper njll. Futhi kwamanye amasilinda akhethekile.

Ukwakhiwa Kwekhemikhali:

| Ukwakheka Kwamakhemikhali | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Ukucaciswa:

| Ukuqina Kwengcindezi (N/mm2) | Amandla Esivuno (N/mm2) | I-Ductility (%) | Ukuqina Kobuso | Ukunemba Kobubanzi Bangaphakathi | Ubulukhuni bangaphakathi | Ukuqondile | Iphutha lokuqina |

| Sb 157 | S 0.2 108 | S8 | I-HV 300 | I-H9-H11 | <0.6 | 1/1000 | ± 1% |

I-Tolerance Of Aluminium Alloy Tube:

| UKUBEKEZANA KWETHUBU LE-ALUMINIUM | ||||||

| Bore Size | UKUBEKEZANA | |||||

| mm | I-H9(mm) | I-H10(mm) | I-H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

I-FAQ:

Q1: Iyini imodeli ye-DFM? A:☆ Kuyinto FESTO standard.Usayizi webhore usuka ku-Dia12mm kuya ku-Dia100mm.

Ukucaciswa:☆Shayela futhi uqondise iyunithi endlini eyodwa

☆ Ukumelana okuphezulu nama-torque kanye namandla aseceleni

☆ Igayidi yebhola engenalutho noma ejikelezayo

☆Izinketho ezibanzi zokukhweza nokunamathiselwe

☆ Uhlu olubanzi lokuhlukahluka kwezinhlelo zokusebenza ezenziwe ngezifiso

Q2: Uma sithenga i-DFM, kungenzeka yini nge-anodizing ye-Aluminium 6063 T5 Cylinder Tube?

IMP: Le Cylinder ye-Pneumatic ayinconywa ukuthi ifakwe i-oxidized, ngoba ikhasimende lidinga ukuzisika ngokwalo bese liyicubungula bese lenza ukwelashwa komoyampilo ngemva kokuyithenga.

Q3: Bungakanani ubude uma siyalaI-Aluminium Extrusion Yamasilinda Womoya?

A:Ubude bungamamitha angu-2.

Q4: Faka imodeli ye-DFM

A:☆Ngedrayivu eqondisiwe ye-DFM, ungathembela ekuqondisweni okunembayo kanye nokumuncwa okuhle kwama-torque namandla aseceleni, okuhambisana nomklamo oqinile, ohlangene.Ilungele ukugoqa, ukuphakamisa nokumisa izinhlelo zokusebenza.

Q5: Wisigqokoisikhathi sokulethwamayelana Iphrofayili ye-Aluminium Ye-Air Cylinder?

A: ☆ Uma amashubhu enziwe ngokwezifiso, isikhathi sidinga izinsuku zokusebenza ezingama-50-60, kepha uma ngamashubhu ajwayelekile, isikhathi sethu sokulethwa siyizinsuku zokusebenza eziyi-15-20.