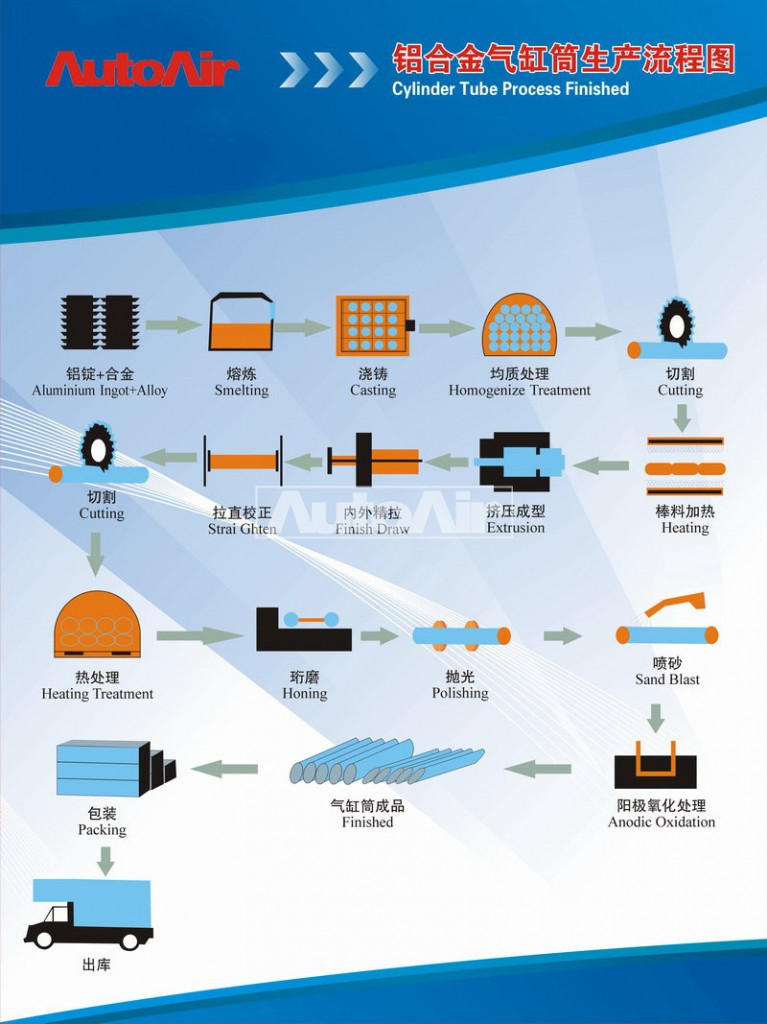

Inqubo Yokukhiqiza Yethubhu Ye-Pneumatic Cylinder

I-workshop ye-Raw Material

I-workshop ye-Raw Material

Extrusion Workshop

Extrusion Workshop

Qedela i-Draw workshop

Qedela i-Draw workshop

I-Workshop Yokuhlonishwa

I-Workshop Yokuhlonishwa

Ishabhu yokupholisha

Ishabhu yokupholisha

I-Sand Blast Workshop

I-Sand Blast Workshop

I-Anodic Oxidation Workshop

I-Anodic Oxidation Workshop

Ukupakisha i-Pneumatic cylinder Tube

Ukupakisha i-Pneumatic cylinder Tube

Ishabhu yempahla elungile

Ishabhu yempahla elungile

Okokuqala, ngemva kokuthola imidwebo eyenziwe ngokwezifiso yekhasimende noma ikhasimende lamukela imidwebo yethu evamile, sizothenga izinto ezingavuthiwe zokuvula isikhunta.

Isinyathelo 1:Iphrofayili ye-Aluminium enwetshiwe ngokomdwebo ngesikhunta

2 amasethi emishini esindayo ye-aluminium extrusion profile

Isinyathelo sesi-2:Qeda ukudweba

Isinyathelo sesi-3:Qondisa

Isinyathelo sesi-4:Ukusika

Isinyathelo sesi-5:Ukwelashwa kokushisisa

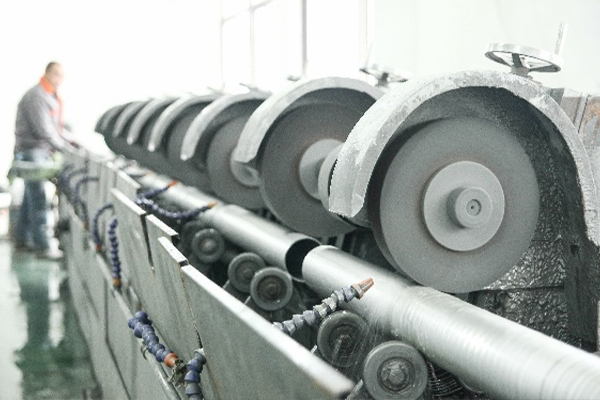

Isinyathelo sesi-6:Ukucija

Amasethi ayi-12 emishini yokucija ishubhu ye-Pneumatic cylinder

I-FAQ:

Q1: Kuyini ukucija?

A: Ukuqedela ukucutshungulwa kwendawo yokuqedela nge-whetstone (ebuye ibizwe ngokuthi i-honing stick) efakwe ekhanda lokuphothula.Kwaziwa nangokuthi kuyisicefe.Ngokuyinhloko icubungula izimbobo ezihlukahlukene ze-cylindrical ezinobubanzi obungu-5 kuya ku-500 mm noma ngisho nangaphezulu, futhi isilinganiso sokujula kwembobo kuya kububanzi bembobo singafinyelela ku-10 noma ngaphezulu.Ngaphansi kwezimo ezithile, ingakwazi futhi ukucubungula izindiza, izindawo ezingaphandle eziyindilinga, izindawo eziyindilinga, izindawo zamazinyo, njll. Isiyingi esingaphandle sekhanda lokuphothula sihuqwe ngamatshe amatshe ama-whetstone angu-2-10 anobude obuyi-1/3 kuya ku-3/4 ubude bomgodi.Lapho ucija imbobo, iyajika futhi ihamba iye emuva naphambili.Ngesikhathi esifanayo, ikhula ngokulinganayo nge-spring noma i-hydraulic control ekhanda le-honing.Ngakho-ke, indawo yokuxhumana enobuso bomgodi inkulu, futhi ukusebenza kahle kokucubungula kuphezulu.Ukunemba kobukhulu bembobo ngemva kokucija yi-IT7~4, futhi ubulukhuni obungaphezulu bungafinyelela ku-Ra0.32~0.04 microns.Usayizi wesibonelelo sokucija uncike kububanzi bembobo kanye nempahla yomsebenzi, ngokuvamile engu-0.02~0.15 mm yezingxenye zensimbi ecijile kanye no-0.01~0.05 mm wezingxenye zensimbi.Isivinini esijikelezayo sekhanda lokucija ngokuvamile singu-100 ~ 200 rpm, futhi isivinini sokunyakaza okuphindaphindayo ngokuvamile singu-15~20 m/min.Ukuze ukhiphe ama-chips okusika kanye nezinhlayiya ezilimazayo, uthuthukise ukuhwalala kwendawo futhi unciphise izinga lokushisa lendawo yokusika, inani elikhulu loketshezi lokusika, olufana nophalafini noma inani elincane likawoyela wokuphotha, livame ukusetshenziswa ngesikhathi sokusebenza, futhi ngezinye izikhathi i-emulsion yokucindezela okwedlulele nayo isetshenziswa.

Isinyathelo sesi-7:Ukupholisha

2 amasethi emishini yokupholisha indawo

Isinyathelo sesi-8:Ukuqhuma kwesihlabathi

2 amasethi emishini yokuqhumisa isihlabathi

FAQ

Q1: Kuyini ukuqhuma kwesihlabathi?

IMPENDULO: Inqubo yokusebenzisa umthelela wokugeleza kwesihlabathi esinesivinini esikhulu ukuze kuhlanzeke futhi kukhuhlazwe ingaphezulu le-substrate.Umoya ocindezelwe usetshenziswa njengamandla ukwenza i-jet beam enesivinini esikhulu ukufafaza izinto zokufutha (itshe lensimbi yethusi, isihlabathi se-quartz, isihlabathi se-emery, isihlabathi sensimbi, isihlabathi sase-Hainan) ngesivinini esikhulu ukuya phezulu kwendawo yokusebenza okufanele iphathwe, ukuze ukubukeka noma ukuma kwendawo yangaphandle yendawo yokusebenza kuyashintshwa , Ngenxa yomthelela nokusika isenzo se-abrasive ebusweni bomsebenzi womsebenzi, ingaphezulu le-workpiece lingathola izinga elithile lokuhlanzeka kanye nobulukhuni obuhlukile, ukuze izakhiwo zemishini ye-workpiece surface ziyathuthukiswa, ngaleyo ndlela kuthuthukiswe ukumelana nokukhathala kwe-workpiece, futhi kwandiswe nokugqoka kwayo Ukunamathela phakathi kwezingqimba kwandisa ukuqina kwefilimu yokugqoka, futhi kubuye kuhambisane nokulingana nokuhlobisa kwe-coating.

Isinyathelo 9:I-anodizing

2 amasethi emigqa yokwelapha ye-anodizing

I-FAQ:

Q1: Iyini i-anodizing?

A: I-anodic oxidation, i-electrochemical oxidation yezinsimbi noma ama-alloys.I-Aluminium nama-alloys ayo yakha ungqimba lwefilimu ye-oxide emikhiqizweni ye-aluminium (i-anode) ngaphansi kwesenzo samanje esisetshenzisiwe ngaphansi kwe-electrolyte ehambisanayo nezimo ezithile zenqubo.Uma i-anodizing ingacacisiwe, ngokuvamile ibhekisela ku-anodizing ye-sulfuric acid.

Ukuze unqobe ukukhubazeka kokuqina kobuso be-aluminium ingxubevange, ukumelana nokugqoka nezinye izici, wandise ububanzi bokusebenza, futhi wandise impilo yesevisi, ubuchwepheshe bokwelashwa kwendawo sebuyingxenye ebalulekile yokusetshenziswa kwe-aluminium alloy, futhi ubuchwepheshe be-anodizing okwamanje esetshenziswa kakhulu futhi ephumelela kakhulu.

Isinyathelo 10:Amashubhu e-aluminium cylinder aqedile

Isinyathelo 11:Ukupakisha amashubhu e-Aluminium cylinder