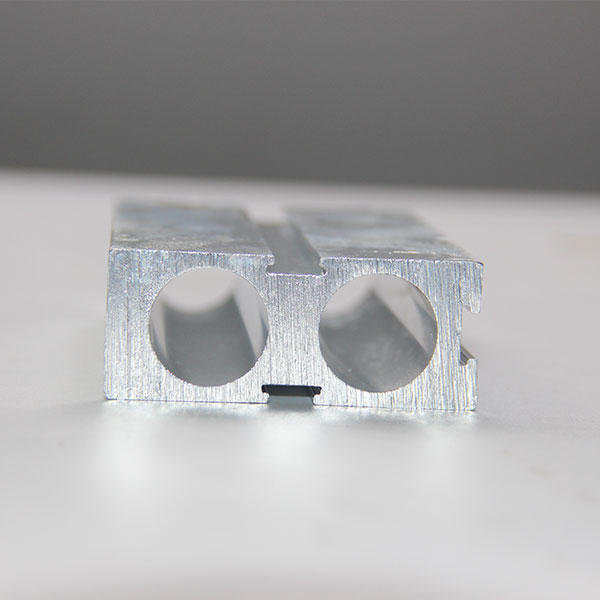

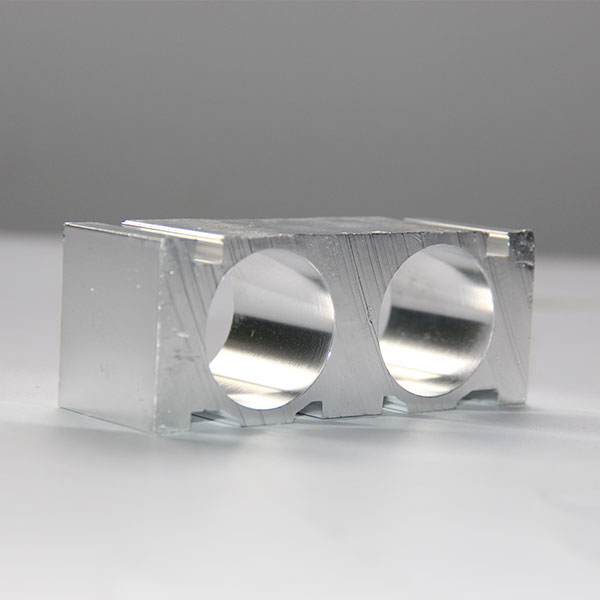

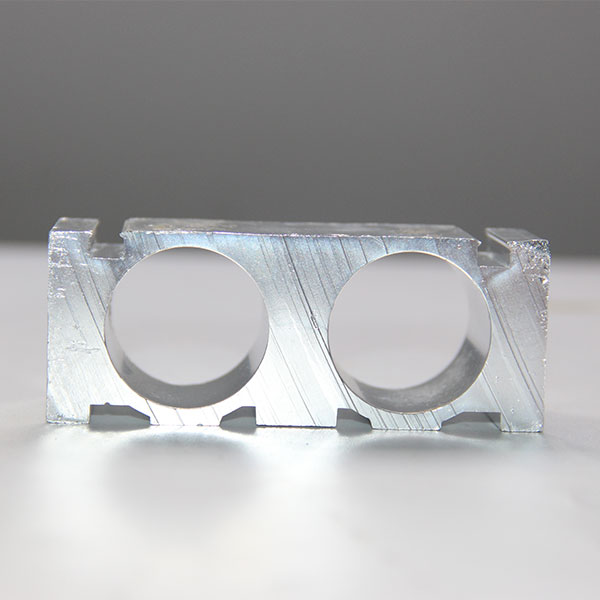

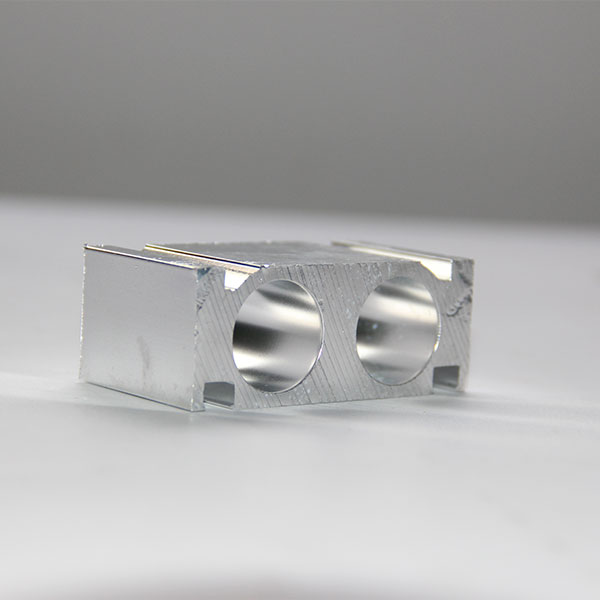

TN/TR/TCM/CXS DUAL ROD AIR CYLINDER ALUMINIUM TUBE

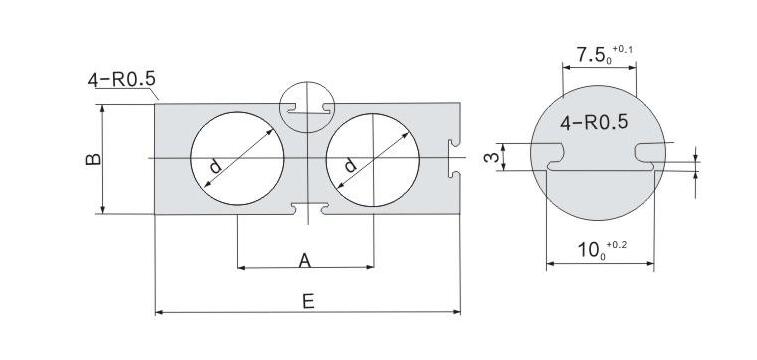

I-TN (φ10-50) Uchungechunge lwe-Dual Rod Cylinder Tube

| No | d | E | A | B |

| 1 | φ10 | 42 | 18 | 17 |

| 2 | φ16 | 54 | 24 | 21 |

| 3 | φ20 | 62 | 28 | 25 |

| 4 | φ25 | 73 | 34 | 30 |

| 5 | φ32 | 96 | 42 | 40 |

| 6 | φ40 | 112 | 56 | 48 |

| 7 | φ50 | 135.5 | 60.5 | 58 |

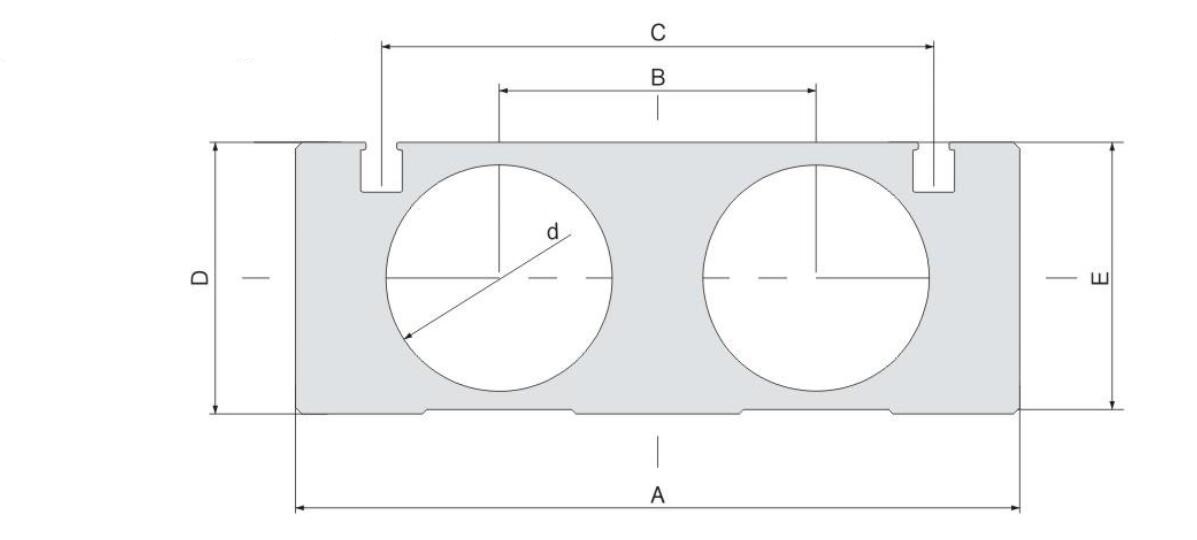

I-TR (φ6-32) Uchungechunge lwe-Dual Rod Cylinder Tube

| NO | d | E | A | T | B | b | D |

| 1 | Φ10 | 46.4 | 20 | 33.8 | 17.3 | 7.3 | 25.8 |

| 2 | Φ16 | 58.5 | 25 | 41.2 | 20.3 | 10 | 33.4 |

| 3 | Φ20 | 64.4 | 28 | 53 | 25.3 | 12.8 | 37.5 |

| 4 | Φ25 | 80.4 | 35 | 64 | 30.3 | 15.3 | 45.5 |

| 5 | Φ32 | - | - | I-P IS ibhekisela ku-belou darwing | |||

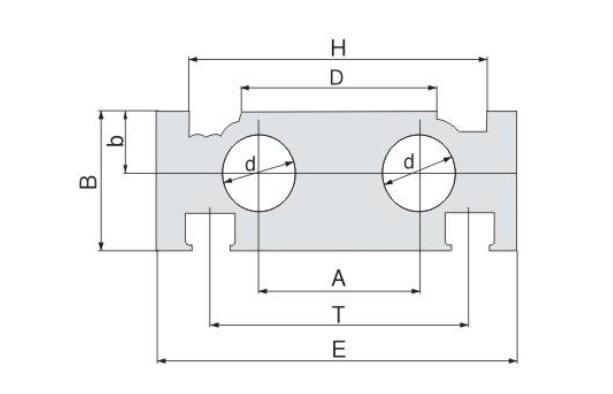

I-CXS (φ10-32) Uchungechunge Lwethubhu yesilinda

| No | d | E | A | T | B | b | D | H |

| 1 | φ10 | 46 | 20 | 33.8 | 17 | 7.1 | 25.8 | 38 |

| 2 | φ15 | 58 | 25 | 41.2 | 20 | 10 | 33.4 | - |

| 3 | φ20 | 64 | 28 | 53 | 25 | 12.5 | 37.5 | 52.5 |

| 4 | φ25 | 80 | 35 | 64 | 30 | 15 | 45.5 | 67 |

| 5 | φ32 | 98 | 48 | 76 | 38 | 19 | 57.5 | 81.2 |

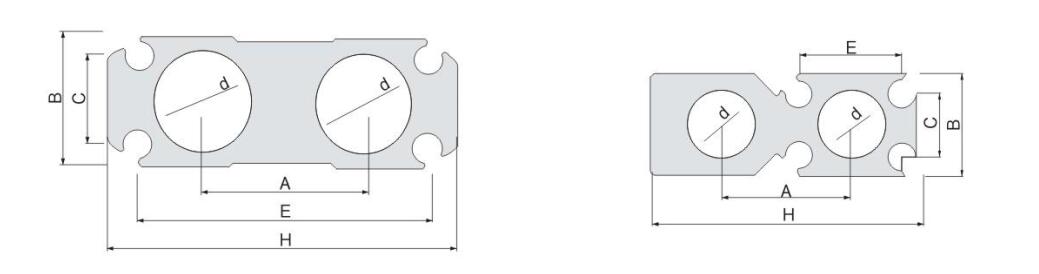

I-CXS-J (φ6-32) Uchungechunge lwe-Dual Rod Cylinder Tube

| NO | d | H | B | A | E | C |

| 1 | φ6 | 32 | 13.4 | 16 | 10.6 | 8 |

| 2 | φ10 | 42 | 15 | 20 | 16 | g |

| 3 | φ15 | 54 | 19 | 25 | 45 | 13 |

| 4 | φ20 | 62 | 24 | 29 | 51 | 18 |

| 5 | φ25 | 73 | 29 | 35 | 59 | 23 |

| 6 | φ32 | 94 | 37 | 45 | 73 | 31 |

I-Material ye-Aluminium Alloy Profile I-Aluminium pneumatic cylinder tube: i-aluminium alloy 6063 T5

Ubude bethu obujwayelekile bungu-2000mm, uma udinga obunye ubude, sicela usazise ngokukhululekile.

Indawo ene-anodized: Ishubhu yangaphakathi-15±5μm Ishubhu yangaphandle-10±5μm

Izivumelwano zokuklama i-FESTO, i-SMC, i-Airtac, i-Chelic njll.

Ivumelana nezinga le-ISO 6430 ISO6431 VDMA 24562 ISO15552 njll.

Isetshenziselwa isilinda esijwayelekile, isilinda esicwebezelayo, isilinda esincane, isilinda se-Dual Rod, isilinda sama-Slide, isilinda seThebula lama-Slide, i-Gripper njll. Futhi kwamanye amasilinda akhethekile.

Ukwakhiwa Kwekhemikhali:

| Ukwakheka Kwamakhemikhali | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Ukucaciswa:

| Ukuqina Kwengcindezi (N/mm2) | Amandla Esivuno (N/mm2) | I-Ductility (%) | Ukuqina Kobuso | Ukunemba Kobubanzi Bangaphakathi | Ubulukhuni bangaphakathi | Ukuqondile | Iphutha lokuqina |

| Sb 157 | S 0.2 108 | S8 | I-HV 300 | I-H9-H11 | <0.6 | 1/1000 | ± 1% |

I-Tolerance Of Aluminium Alloy Tube:

| UKUBEKEZANA KWETHUBU LE-ALUMINIUM | ||||||

| Bore Size | UKUBEKEZANA | |||||

| mm | I-H9(mm) | I-H10(mm) | I-H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

I-FAQ:

Q1: Iyini i-dual rod pneumatic cylinder?

A: I-dual rod pneumatic cylinder ingumsebenzi wama-piston rods amabili kusilinda somoya enza ukunyakaza okuphindaphindayo okulandelanayo kusilinda womoya ukuze kukhiqizwe umfutho womoya, futhi umfutho womoya uphusha ipiston ukuthi ikhiqize ukuphonseka nokunwebeka kumandla omshini.Izindawo zohlelo lokusebenza zamasilinda womoya s: ukuphrinta, ama-semiconductors, ukulawula okuzenzakalelayo, amarobhothi, njll.

Q2: Kungani usebenzise i-double piston rod yesilinda somoya?

A: Isakhiwo se-double-piston rod senza isilinda somoya sibe nokusebenza okuhle kwe-anti-goba kanye ne-anti-torsion, futhi singakwazi ukumelana nemithwalo emikhulu ehambayo kanye nemithwalo yangemuva.

Kunamadivayisi ephedi avimbela ukushayisana emikhawulweni yomibili, enganciphisa ngempumelelo isivinini somthelela futhi andise impilo yesevisi.

I-Q3: Yimaphi amamodeli we-pneumatic cylinder ene-double piston rod?

A: I-Dual rod pneumatic cylinder ine-SMC standard CXSM, Airtac standard TN, Airtac standard STM njll.

Q4: Ingabe kukhona okujwayelekile nge-SMC noma i-Airtac?

A: Impela, sivumelana nezinga labo lokukhiqiza.

Q5: Yini okufanele uyinake lapho usebenzisa isilinda somoya?

A: Ngaphansi kwezinga lokushisa eliphezulu noma izimo ezibolayo, kufanele kusetshenziswe amasilinda omoya amelana nezinga lokushisa eliphezulu noma amasilinda womoya ogqwalile.