Uchwepheshe WaseShayina WaseShayina S45c SAE1045 C45 Ishidi Lensimbi Egingqiwe Yekhabhoni Eshisayo

Thatha umthwalo ogcwele wokufeza zonke izidingo zamakhasimende ethu;sifinyelele intuthuko eqhubekayo ngokuthuthukisa ukukhula kwamakhasimende ethu;ube nguzakwethu wokugcina wokubambisana unomphela wamakhasimende futhi wandise izintshisekelo zamakhasimende e-Chinese Professional China S45c SAE1045 C45 Ishidi Lensimbi Eshisiwe Lekhabhoni Eshisayo, Sikholelwa ukuthi ngekhwalithi enhle ngaphezu kobuningi.Ngaphambi kokuthunyelwa kwezinwele kwamanye amazwe kunokuhlolwa okuqinile kokulawulwa kwekhwalithi ephezulu ngesikhathi sokwelashwa ngokwezindinganiso zekhwalithi ezinhle zomhlaba wonke.

Thatha umthwalo ogcwele wokufeza zonke izidingo zamakhasimende ethu;sifinyelele intuthuko eqhubekayo ngokuthuthukisa ukukhula kwamakhasimende ethu;ube nguzakwethu wokugcina wokubambisana wamakhasimende futhi wandise izintshisekelo zamakhasimendeChina Steel Sheet, Ishidi Lensimbi Eligoqiwe Elishisayo, Ithimba lethu lizazi kahle izimfuno zemakethe emazweni ahlukene, futhi liyakwazi ukuhlinzeka ngemikhiqizo esezingeni elifanele nezisombululo ngamanani angcono kakhulu ezimakethe ezahlukahlukene.Inkampani yethu isivele isungule ithimba elinolwazi, elinobuchule nelinomthwalo wemfanelo ukuthuthukisa amakhasimende ngomgomo wokunqoba okuningi.

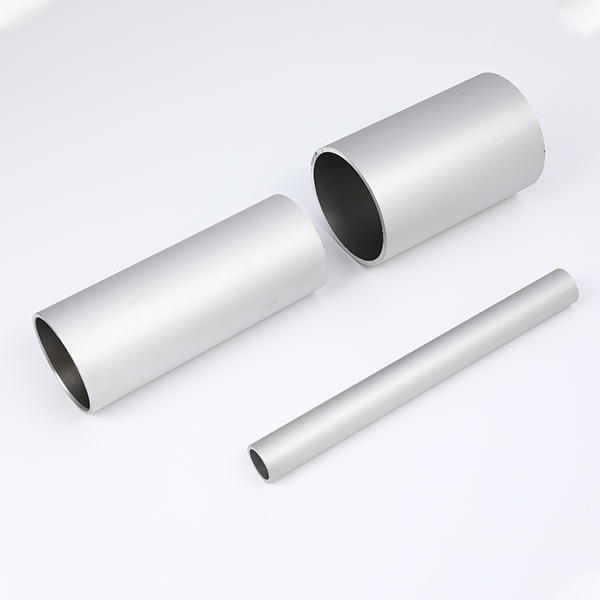

I-pneumatic cylinder hydraulic piston rod ibizwa nangokuthi i-chrome-plated rod.Yinduku enendawo engaphezulu ephathwa ngokugaya okukhethekile kanye nokufakwa kwe-chrome eqinile.Isetshenziswa kabanzi kumasilinda ahlukahlukene, amasilinda amanzi, ukupakisha, ukusebenza ngokhuni, ukuphotha, ukuphrinta kanye nemishini yokudaya, izingxenye ze-die-casting namanye amadivaysi okudlulisela okuzenzakalelayo ngenxa yokuqina kwawo, okunganweba impilo yesevisi yemishini yokunemba evamile kanye nemishini.

Samukela ukubanda okunembayo okudonsayo, ukucija nokupholishwa ukuze sikhiqize i-pneumatic cylinder hydraulic piston rod, zonke izinjongo zobuchwepheshe zihlangabezana nezinga lezwe.

Ukucaciswa Kwemininingwane

Izinto: CK45(GB/T699-1999)

Ukucaciswa komshini:

Amandla okuqina(Mpa):≥600N/mm2

0,2 Yield Stress(Mpa):≥355N/mm2

Ubude:min.16%

Ubukhulu obucwecwe be-Chrome: φ<20mm≥15μm,kusuka ku-φ20mm>20μm

Ubulukhuni: Ra<0.2

Ukuqina kwe-Chrome Layer:850HV-1050HV

Ukubekezelela Ububanzi: f7,f8

Ukuqina: <0.1um/1000mm

I-ovality: <1/2 ukubekezelela ububanzi

Ukuhlolwa kwe-Corroseston Test:ISO 10289:1999,IDT

Ububanzi bangaphandle:3-120mm (GCr15) 3-40m(SUS440C)

Isimo sokulethwa:Okuvamile,I-Induction Harden,Q+T

Ithebula lokwakheka kwamakhemikhali

| UKWAKHIWA KWEKHEMICAL(%) | |||||||

| Okubalulekile | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0,50 | 0.50-0.80 | 0.17-0.37 | 0.035 | 0.035 | ||

| ST52 | <=0.22 | <=1.6 | <=0.55 | 0.035 | 0.035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.1-0.50 | 0.035 | 0.035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Kr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 | |||

| Ububanzi | Isisindo | Ukubekezelelana | Ukubekezelelana | Ukubekezelelana |

| mm | Kg/m | f7 (μm) | f8(μm) | h6(μm) |

| 6 | 0.22 | -10–22 | -10–28 | 0–9 |

| 8 | 0.39 | -13–28 | -13–35 | 0–9 |

| 10 | 0.62 | -13–28 | -13–35 | 0–11 |

| 12 | 0.89 | -16–34 | -16-43 | 0–11 |

| 16 | 1.58 | -16–34 | -16-43 | 0–11 |

| 18 | 2.00 | -16–34 | -16-43 | 0–13 |

| 20 | 2.47 | -20–41 | -20–53 | 0–13 |

| 22 | 2.99 | -20–41 | -20–53 | 0–13 |

| 25 | 3.86 | -20–41 | -20–53 | 0–13 |

| 28 | 4.84 | -20–41 | -20–53 | 0–13 |

| 30 | 5.55 | -20–41 | -20–53 | 0–16 |

| 32 | 6.32 | -25-50 | - 25-64 | 0–16 |

| 36 | 8.00 | -25-50 | - 25-64 | 0–16 |

| 38 | 8.91 | -25-50 | - 25-64 | 0–16 |

| 40 | 9.87 | -25-50 | - 25-64 | 0–16 |

| 45 | 12.49 | -25-50 | - 25-64 | 0–16 |

| 50 | 14.22 | -25-50 | - 25-64 | 0–19 |

| 55 | 15.43 | - 30-60 | - 30-76 | 0–19 |

| 60 | 18.66 | - 30-60 | - 30-76 | 0–19 |

| 65 | 26.07 | - 30-60 | - 30-76 | 0–19 |

| 70 | 30.23 | - 30-60 | - 30-76 | 0–19 |

| 75 | 34.71 | - 30-60 | - 30-76 | 0–19 |

| 80 | 39.49 | - 30-60 | - 30-76 | 0–22 |

| 85 | 44.58 | - 36-71 | - 36-90 | 0–22 |

| 90 | 49.98 | - 36-71 | - 36-90 | 0–22 |

| 95 | 55.68 | - 36-71 | - 36-90 | 0–22 |

| 100 | 61.70 | - 36-71 | - 36-90 | 0–22 |

Ayini amazinga okubekezelela okuthi f7 kanye ne-f8:

Ibanga lokubekezelela le-f8 likhulu kunalelo le-f7, futhi ukufakwa kuncike ezingeni lendawo yokubekezelela imbobo efanayo.Isibonelo, uma usayizi oyisisekelo ungu-10-18, f8(-0.016,-0.034), f7(-0.016,-0.027), ukuchezuka kokubekezelelana okubili kuyafana, ububanzi be-f7 buncane, kanye nokuvunyelwa ububanzi bokulingana kokufaka buncane.

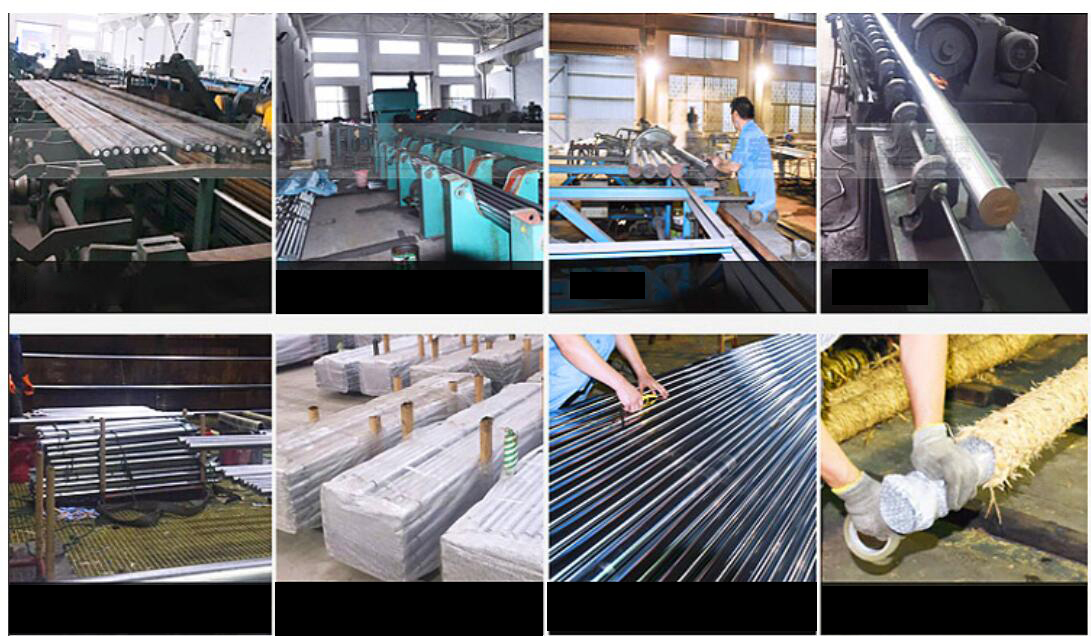

Ukugeleza Kokukhiqiza

Isinyathelo esingu-1: Ukucwecwa/Ukudwetshwa Okubandayo:

Umdwebo obandayo ubuchwepheshe bokucubungula we-pneumatic cylinder piston rod.Ku-cylinder ye-pneumatic hard chrome plated rod, umdwebo obandayo ubhekisela ekudwebeni ngaphansi kwesimo sokushisa okuvamile ukuze kuzuzwe ukuma okuthile kanye nezakhiwo ezithile zemishini.Uma kuqhathaniswa nokwakheka okushisayo, imikhiqizo edonswa ngokubanda inezinzuzo zokunemba kobukhulu obuphakeme kanye nokuqedwa okungcono kwendawo.

2 Isinyathelo: Ukuqondisa

Lesi sinyathelo singenza isiqiniseko sokuthi induku ye-chrome plated iqonde ngokwanele.Kubaluleke kakhulu, uma uyifaka ngaphakathi kwe-cylinder ye-pneumatic.Ukuqondisa okujwayelekile kungu-0.2mm/m.

3 Isinyathelo: Ukucija

Ukucubungula i-Honing kuyindlela yokucubungula ephumelelayo eyenza indawo ye-pneumatic cylinder piston rod ifinyelele ukunemba okuphezulu, ikhwalithi ephezulu kanye nempilo ende.Ingakwazi ukuthuthukisa ngempumelelo ukunemba kobukhulu, ukunemba komumo futhi yehlise inani lika-Ra, kodwa ayikwazi ukuthuthukisa indawo yembobo nezinye izindawo.

4 Isinyathelo: Ukupholisha induku yensimbi

Ukupholisha kubhekisela ekusetshenzisweni kwemishini, amakhemikhali noma imiphumela ye-electrochemical ukunciphisa ukuhwalala kwangaphezulu kwe-pneumatic cylinder piston rod ukuze kutholwe indawo ekhanyayo nebushelelezi.Kuwukusetshenziswa kwamathuluzi okupholisha nezinhlayiya ezilumayo noma enye imidiya yokupholisha ukuze kulungiswe ingaphezulu lenduku yepiston yesilinda somoya.

5 Isinyathelo: I-Chrome Plating

I-Chrome plating ibhekisela esenzweni sokucwenga i-chromium njengesimbozo senduku ye-pneumatic hard chrome plated.

Isendlalelo esifakwe nge-chromium sinokuqina okuphezulu kakhulu, futhi ubulukhuni baso bungahluka phakathi kwebanga elibanzi le-400-1200HV ngokuya ngokubunjwa kwesixazululo sokucwenga nezimo zenqubo.Isendlalelo se-chrome-plated sinokumelana kahle nokushisa.Uma kushisa ngaphansi kuka-500 ℃, alukho ushintsho olusobala ekucwebezeleni nasekuqineni.Izinga lokushisa lizoqala ukwenza i-oxidize futhi lishintshe umbala lapho izinga lokushisa lingaphezu kuka-500℃, futhi ubulukhuni buzokwehla uma bungaphezu kuka-700℃.I-coefficient ye-friction yesendlalelo se-chrome incane, ikakhulukazi i-coefficient eyomile, ephansi kakhulu kuzo zonke izinsimbi.Ngakho-ke, isendlalelo se-chrome-plated sinokuphikiswa okuhle kokugqoka.

Isendlalelo se-chromium plating sinokuzinza okuhle kwamakhemikhali.Ayinawo umphumela ku-alkali, i-sulfide, i-nitric acid kanye nama-asidi amaningi e-organic, kodwa ingancibilika ku-pneumatic acid (njenge-pneumatic acid) kanye ne-hot sulfuric acid.Kububanzi bokukhanya obubonakalayo, ukukhanya kwe-chromium cishe kungama-65%, okuphakathi kwesiliva (88%) ne-nickel (55%).Ngenxa yokuthi i-chromium ayishintshi umbala, ingakwazi ukulondoloza ukubukeka kwayo isikhathi eside futhi ingcono kunesiliva ne-nickel.

6 Isinyathelo: I-Chrome plated induku Ukupholisha ngemva kokucwenga

I-Electroplating kanye nokupholisha: izindlela ezimbili ezihlukene zokwelashwa okungaphezulu kwezinsimbi nezinye izinto.Owokuqala ukwelapha ngamakhemikhali, kanti okugcina kuwukwelapha ngomshini.

I-Electroplating: Inqubo yokusebenzisa i-electrolysis ukunamathisela ungqimba lwefilimu yensimbi ebusweni bensimbi noma enye into.Ingavimbela ukugqwala, ithuthukise ukumelana nokugqokwa, i-conductivity kagesi, i-reflection futhi ithuthukise ubuhle.

Ukupholisha: Sebenzisa amathuluzi okupholisha avumelana nezimo kanye nezinhlayiya ezilumayo noma enye imidiya yokupholisha ukuze ulungise indawo yokusebenza.Ukupholisha akukwazi ukuthuthukisa ukunemba kwe-dimensional noma ukunemba kwejometri ye-workpiece, kodwa kuhloswe ukuthola indawo ebushelelezi noma isicwebezelisi sesibuko.

7 Isinyathelo: Ukuhlolwa kwekhwalithi ye-Chrome plated

Izinti ze-piston eziye zabhekana nezinqubo ze-electroplating kanye ne-polishing zivame ukuhambisana neziphambeko zokumboza njengemigodi ye-chrome ne-pitting.Ubukhulu kanye nenani lalezi ziphambeko kuthinta ngokuqondile ukusebenza kwe-piston rod.Ukunciphisa umthelela walezi ziphambeko ku-piston rod, ngakolunye uhlangothi, ngokwenza ngcono ikhwalithi yezinto ezingavuthiwe, ukuthuthukisa ubuchwepheshe bokucubungula, nokunciphisa ukuvela kokukhubazeka;ngakolunye uhlangothi, kuyadingeka ukuthola ngokunembile iziphambeko ze-plating ngemva kwenqubo yokupholisha ukuze ugweme imikhiqizo engafaneleki ekuphumeni kwemboni.Onjiniyela be-Autoair bathola iphutha elizenzakalelayo ngosizo lolwazi lwesayensi yezithombe

8 Isinyathelo: Ukupakisha

I-FAQ:

Q1:Iyini induku ye-pneumatic cylinder piston?

A:I-piston rod iyisici esibalulekile nesibalulekile kuwo wonke ama-cylinder omoya noma womoya.I-piston rod iwubude obunemba obufakwe ngomshini bensimbi eqinile ene-chrome plated epholile edlulisa amandla adalwe ipiston engxenyeni yomshini owenza umsebenzi.

Q2: Uyini umgomo we-pneumatic cylinder piston rod?

A: Ipistoni yesilinda somoya esisilinda ithwala amandla okucindezela noma okudonsa akhiqizwa umoya, futhi isebenza ngokuqondile endongeni yepiston ye-pneumatic cylinder exhunywe nepiston, bese kuthi i-pneumatic cylinder piston rod ixhunywe endaweni yokusebenza ukuze ihambe. emuva naphambili.

Q3:Iyini impahla eluhlaza yenduku yakho ye-pneumatic cylinder piston

A: Imvamisa, induku yepiston yesilinda womoya yesilinda somoya izokhetha 45# insimbi njengento eluhlaza.Uma isilinda esikhiqiziwe sidinga ukusetshenziswa endaweni ekhethekile, insimbi engagqwali engu-304 nayo ingasetshenziswa

Q4: Kungani ukhethe 45 # steel njengoba impahla eluhlaza

A:45# steel iyinsimbi yesakhiwo sekhabhoni yekhwalithi ephezulu enobulukhuni obuphansi nokusika okulula.Ngemva kokucisha, ubulukhuni bayo bobuso bungafinyelela ku-45-52HRC.Futhi ingaba nokusebenza okungcono kakhulu kokusika namandla aphakeme, ukuqina nezinye izici ezibanzi zemishini, ngakho-ke ingenye yezinto ezisetshenziswa kakhulu izingxenye ze-shaft.

Q5:Iyini inqubo yomshini wenduku yakho ye-pneumatic cylinder piston?

A: Ukuze uthole ikhwalithi yomshini ozinzile, ukuqondisa ngesandla kwe-piston rod akuvunyelwe ngemva kokuqala komshini.Ngakho-ke, inqubo yokuqondisa kufanele yenziwe ngaphambi komshini.Ngenxa yokuqina okungalungile kwe-workpiece, ukuphenduka okungalungile kanye nokuphenduka okuhle kufanele kwenziwe ngesikhathi senqubo yomshini ukuze kuthuthukiswe ukunemba kwemishini.Imodi yokusebenza ye-piston rod ibuyisela ukunyakaza komugqa.Ukuze uthuthukise impilo yesevisi ye-piston rod, indawo engaphezulu kufanele ifakwe i-chrome-plated ukuze kuthuthukiswe ubulukhuni bayo bendawo nokumelana nokugqoka.Ngemuva kokufakwa kwe-chrome, ukwelashwa kokupholisha kuyadingeka ukuze kutholwe ukuhwalala okuphezulu kwendawo, ukunciphisa isici sokungqubuzana, nokuthuthukisa ukusebenza kokuvala.Njengoba inqubo yokupholisha icishe ingabi nawo umthelela kububanzi bangaphandle be-piston rod, isiqeshana sokusebenza sidinga ukuzuza ubulukhuni obuphezulu ngaphambi kokufakwa kwe-chrome.Ngakho-ke, kuyadingeka ukwengeza inqubo yokugaya emihle ngaphambi kwenqubo ye-chrome plating (ukugaya ngokunemba kungathuthukisa nokunamathela kwendawo ye-chromium. ).Ngokusekelwe ekuhlaziyweni okungenhla, izinqubo zokucubungula ezinengqondo kakhulu ze-piston rod yilezi: ukuqondisa-rough turning-fine turning-fine grinding-chrome plating-polishing.

Q6: Kuyini ukupholishwa kwenduku ye-pneumatic cylinder piston

A:Ngesikhathi sokuphenduka, imbobo emaphakathi edlala indima yokuma izokhombisa izinga elithile lokuguga.Ukuze kuqinisekiswe isimiso esihlanganisiwe samabhentshimakhi, imbobo emaphakathi kufanele incishwe ngaphambi kokugaya ukuze kuqinisekiswe ikhwalithi yokucubungula.Lapho ugaya, ukugaya ukuhlolwa kufanele kwenziwe embuthanweni wangaphandle eduze nokuphela kuqala, futhi ukugaya induku ye-piston kungenziwa kuphela lapho isimo se-runout sihlangabezana nezidingo zokucubungula.Ngokungeziwe ekuthuthukiseni ukunemba kobukhulu, inqubo yokugaya kahle futhi idinga ukuthola ukuhwaqeka okuphezulu kwendawo emshinini ukuze kuthuthukiswe ukuhlobana kwama-ion e-chromium phakathi nenqubo ye-electroplating.Ukuze kuqinisekiswe ukuthi ukujiya kongqimba lwe-chromium plating lwe-piston rod yokugcina lufana, ubulukhuni obungaphezulu ngemva kokugaya kahle kufanele busondele ekumangelekeni kwendawo ngemva kokucwecwa kwe-chromium nokupholishwa.Uma ubulukhuni obungaphezulu be-piston rod budingeka ukuba bube phezulu, njenge-Ra <0.2 μm, kufanele bucoliseke.Engeza ukugaya okuhle kakhulu noma inqubo yokupholisha ngemva kokugaya.

Thatha umthwalo ogcwele wokufeza zonke izidingo zamakhasimende ethu;sifinyelele intuthuko eqhubekayo ngokuthuthukisa ukukhula kwamakhasimende ethu;ube nguzakwethu wokugcina wokubambisana unomphela wamakhasimende futhi wandise izintshisekelo zamakhasimende e-Chinese Professional China S45c SAE1045 C45 Ishidi Lensimbi Eshisiwe Lekhabhoni Eshisayo, Sikholelwa ukuthi ngekhwalithi enhle ngaphezu kobuningi.Ngaphambi kokuthunyelwa kwezinwele kwamanye amazwe kunokuhlolwa okuqinile kokulawulwa kwekhwalithi ephezulu ngesikhathi sokwelashwa ngokwezindinganiso zekhwalithi ezinhle zomhlaba wonke.

Uchwepheshe waseShayinaChina Steel Sheet, Ishidi Lensimbi Eligoqiwe Elishisayo, Ithimba lethu lizazi kahle izimfuno zemakethe emazweni ahlukene, futhi liyakwazi ukuhlinzeka ngemikhiqizo esezingeni elifanele nezisombululo ngamanani angcono kakhulu ezimakethe ezahlukahlukene.Inkampani yethu isivele isungule ithimba elinolwazi, elinobuchule nelinomthwalo wemfanelo ukuthuthukisa amakhasimende ngomgomo wokunqoba okuningi.